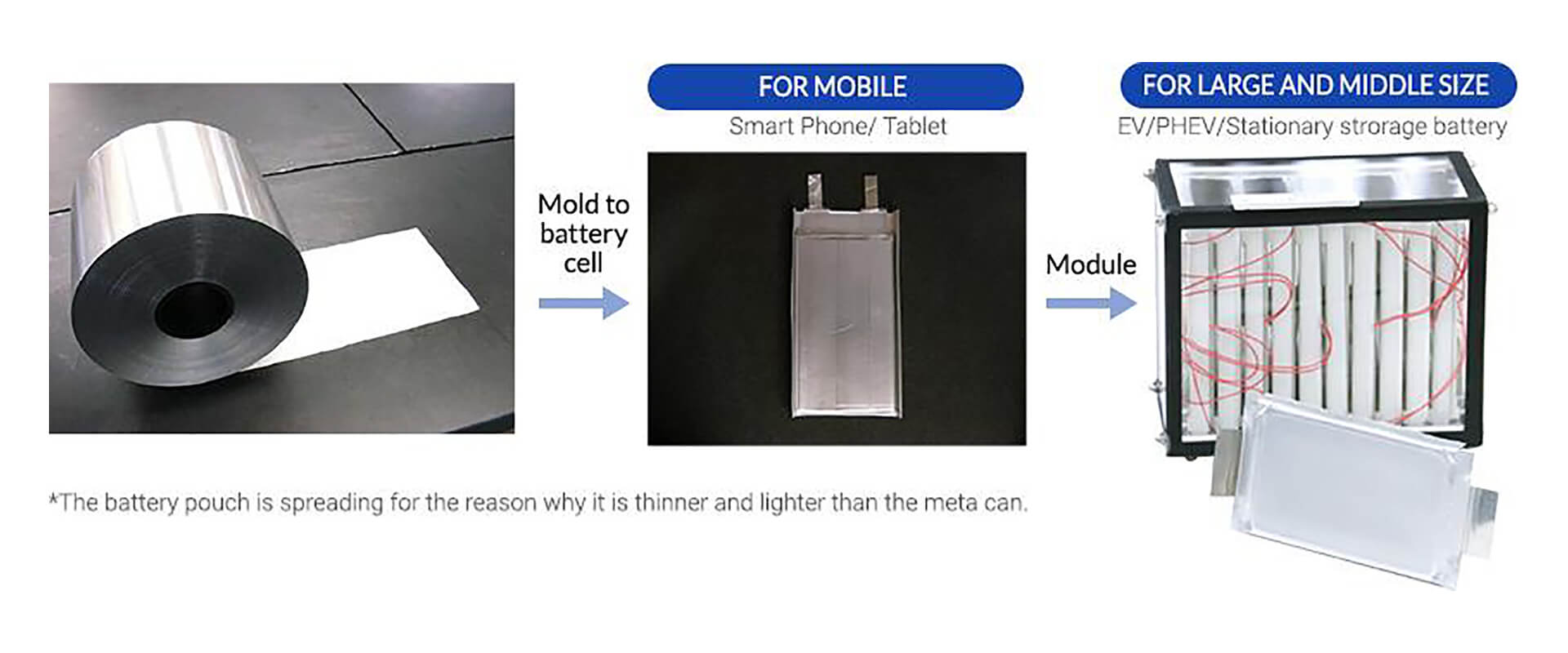

In addition to being used in mobile devices, the use of lithium batteries is also expanding to electric vehicles and residential applications. Battery pouch material for lithium batteries effectively maintains its size and shape with high flexibility. It also uses advanced coating technology and material design to help prevent moisture and aid in forming.

Battery pouches for lithium-ion batteries that use these features offer a high level of durability, as well as receiving high level feedback from various companies that are pushing to promote products that are more lightweight and thin.